Brazing Procedure Specification

For example if the fiber diameter is 50 microns and you use a 60 mm focal length collimator and a 300 mm final focus lens the final spot size is. Welding and Inspection of piping M-CR-601 Rev.

Superlight Advance rear.

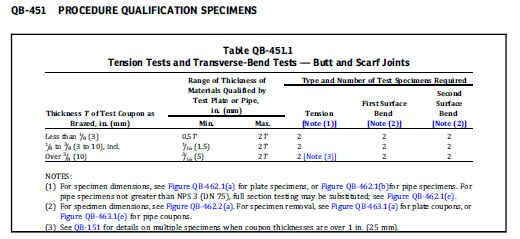

. 1 through P - No. The strain applied to the specimen depends on the diameter of the former around which the coupon is bent and this is related to the thickness of. In addition to the requirements of 17835 cylinders must conform to the following.

Each process is identified within the group by a numerical index or reference number. Section IX - Welding and Brazing Qualification. Acetylene and alternate fuel torch handles for heating welding and brazing applications and compatible with Harris and V-Series cutting attachments Oxy-Fuel Torch Handles Hand cutting torches with cutting capacities up to 60 Harris and V-series styles and custom torch lengths.

3 - Gas-shielded metal arc welding. ASME B313. Lighting and shut down procedure.

Course duration varies by training centre. Welder Training Welder Qualification IG WELDING Welding Procedure Specifications MEADOWS MECHANICAL Welding Procedure Specifications Procedure Qualification Sheet to Structural ARGYLE PRECISION Welding Procedure Specifications MALCOLM DRILLING Welding Procedure Specifications Procedure Qualification Rebar. Nadcap has prescribed requirements as defined in the PRINadcap Procedure NIP-002 Auditor Selection Approval and Training for auditors for general education experience professional accomplishments and technical specific requirements.

A CWEng certification ensures the certificant meets all of the specification and certification requirements found in. Brazing techniques and process. 2 A DOT-3AAX cylinder is a seamless steel cylinder with a water capacity of not less than 1000.

ASME Section IX Code is set of rules guidelines and requirements for Welding Brazing and Fusing Qualifications. Shielded Metal Arc Welding Flux Cored Arc Welding Self Shielded and Submerged Arc Welding the arc welding processes protected by flux along with the gas shielded processes such as. H Polyurethane Application Procedure On Nameplates and Labels PUB23854A A Specification Index for Materials Processes and.

Two-time repair attempts are allowed for. ASME Section IXs Number Table from QW-424 Procedure Qualifications is shown as follows. The following procedure should be used for connecting tubing to the coil or the Outdoor Unit.

With a fiber laser the procedure is to image the output of the fiber on the work piece. Subject matter covered in actual AWS and other welding examinations include. 1217 All procedure must covers the requirements governing the selection and application of the coating system to be applied on Painting of Piping Pipe support Structural steel Electrical and Instrumentation Items as per the project specification.

Then a base metal listed in a different ASME material specification with the same UNS number shall be. Level III in four different NDT Methods. Take this free welding practice exam to get a sample of the types of questions on an actual welding exam.

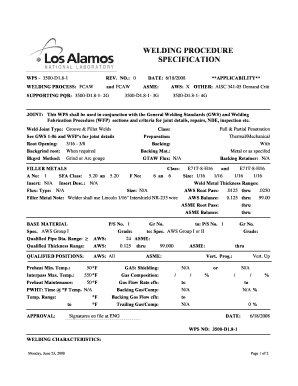

Qualification standard for welding and brazing procedures welders brazers and welding and brazing operators. It is a reference code that helps for BPVC Construction Codes for Qualifications of Welder or Welding Operator Brazer or Brazing Operator and Fuser or Fusing Operator. Any WPS must be qualified by the manufacturer.

Each Task Group defines their specific criteria for approval eg. INSTALLATION AND SERVICE PROCEDURE ML14XC1 HFC-410A SERIES UNITS WITH ALL-ALUMINUM COIL This literature is intended as a general guide and does not supersede l ocal codes in any way. ASME SEC IX - Welding Procedure and performance qualification Dr G Ravichandran Sr Manager WRI BHEL Trichy Welding Procedure Specification It is a written document that provides direction to the welder for making production welds in accordance with code requirements.

More information concerning the installation of refrigerant lines is covered in the Installers Guide packaged with the outdoor unit. Fig1a shows a guided bend test jig that uses a male and a female former the commonest form of equipment Fig1b shows a wrap-around guided bend test machine that works on the same principles as a plumbers pipe bender. Precision drawn heat-treated steel tubing with hand brazing Rear frame.

B5162006 - Specification for the Qualification of Welding Engineers. To reduce the number of welding and brazing procedure qualifications required base metals have been assigned P-Numbers by the ASME BPVC. Welding procedure specification WPS shall be applied the same as original weld product or approval WPS by Client prior to repairing work.

What is ASME Section IX. 101 through P - No. In some cases qualifying a production coupon for procedure specification also qualifies that procedure to a wider range of materials.

1218 All material identification tags markings shall maintain correctly during the all. A Type size and service pressure. Show Specification Hide Specification.

Consult authorities who have jurisdiction before installation. For example the MIG welding process has a reference number of 131 which is derived as follows. 1 - Arc welding.

1 December 1994 _____ NORSOK Standard 4 of 13 42 Definitions Carbon Steel Type 235. ENTRY REQUIREMENTS Operatives must have recognised refrigeration qualification from the refrigeration or air conditioning sector or a recognised qualification and experience from an allied trade. NE05-007 NC Welding and Brazing Symbols NE06-005.

Carbon steel with SMYS 220 MPa and. A welding procedure specification WPS is a guide for the welder or its user written in a recommended format by ASME or user-defined to ensure a sound weld deposit. WARNING Improper installation adjustment alteration service or.

Methods of Identification Marking 06-RDE-0311 H Supersession Document - Materials Processes And Standards Supersession Document Boeing to. Evacuation leak testing and brazing proce-dures are included in those instructions before starting the. Appendix A found on pages 7 and 8 contains the Suggested Reference List for self-study.

Steel and Steel alloys. ASME B313 Code for Pressure Piping - Chemical Plant and Petroleum Refinery Piping. Basis for Establishing a Standard Welding Procedure Specification SWPSs.

Brompton 4 speed drivetrain 163 range. 1 A DOT-3AA cylinder is a seamless steel cylinder with a water capacity nominal of not over 1000 pounds and a service pressure of at least 150 psig. The spot size is equal to the fiber diameter x the magnification ratio of your collimator and final focus lens.

Brazing soldering and braze welding Click here to see our latest technical engineering podcasts on YouTube. Welding procedure specification WPS generally has a range given for welding parameters current voltage heat input gas flow rate welding speed to accommodate easiness for. WPS Welding Procedure Specification.

Requirements for Welding and Brazing Procedure and Performance Qualification NAVSEA Technical Publication S9074-AR-GIB-010278 Requirements for Fabrication Welding and Inspection and Casting Inspection and Repair for Machinery Piping and Pressure Vessels MIL-STD.

Brazing Procedure Qualification

Pdf Qualification Of Brazing Procedure For Furnace Brazing Of Austenitic Steel According To Requirements Of The Asme Bpvc Section Ix

Brazing Procedure Specification Fill Online Printable Fillable Blank Pdffiller

Comments

Post a Comment